From Clashes to Coordination: Mastering MEP Drafting for Project Success

1. Introduction: Why MEP Drafting Is More Than Just Drawings

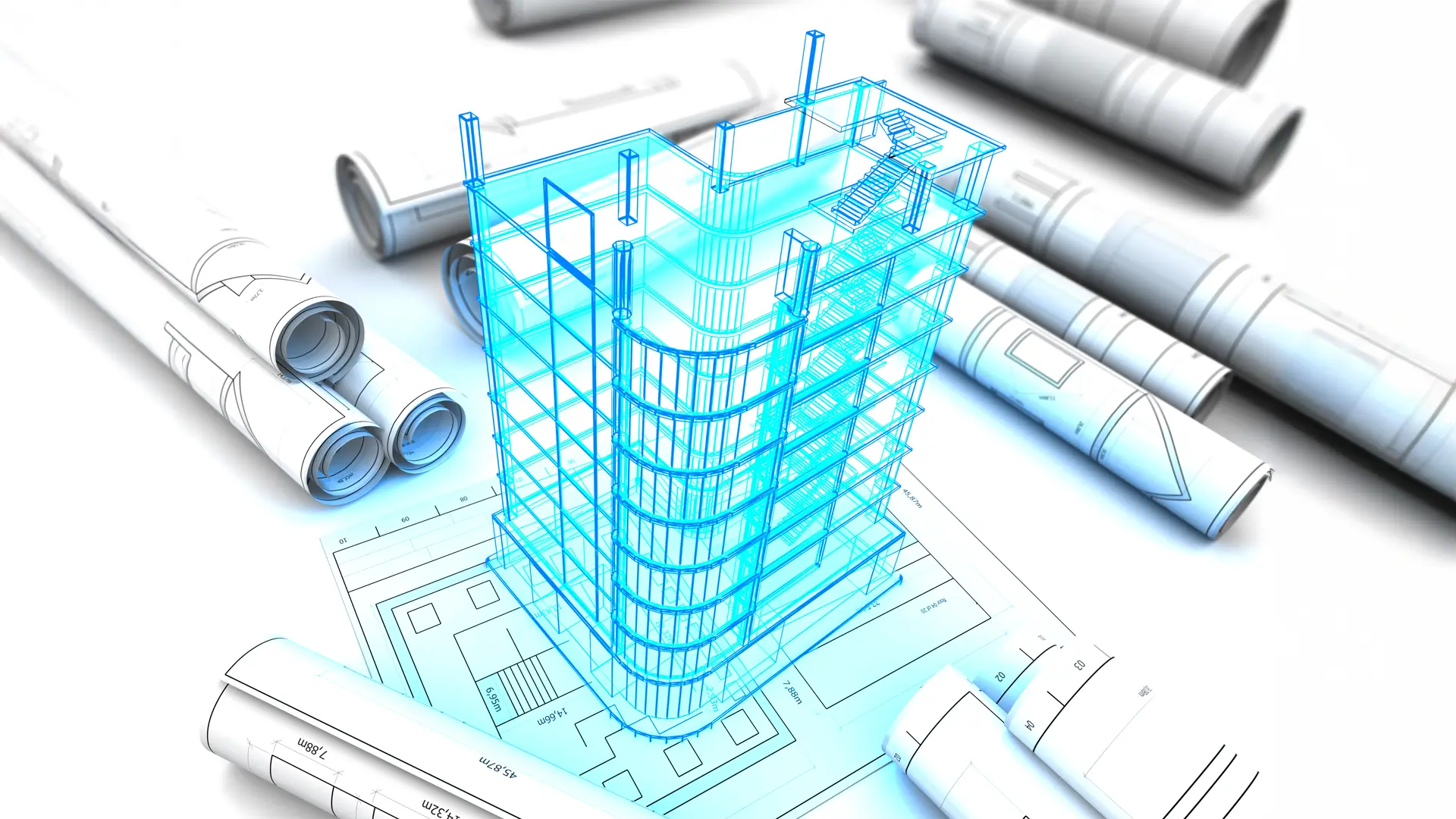

In the complex symphony of modern construction, where steel, concrete, and glass come together, there exists a hidden, yet absolutely critical, backbone: MEP (Mechanical, Electrical, and Plumbing) drafting. Too often seen as a mere technicality, MEP drafting is, in fact, the lifeblood of a building’s functionality. It’s the detailed blueprint that ensures every wire, pipe, and duct fits perfectly, communicating the intricate design intent to the construction teams on-site.

At its core, MEP drafting is about one thing: coordination. A small mistake in a drawing—a pipe clashing with a structural beam or an electrical conduit intersecting a ventilation duct—can lead to massive headaches, costly delays, and a project spiraling out of control. The precision and accuracy of these drawings are not just a luxury; they are a non-negotiable requirement for the success of any modern construction project.

2. Common Challenges in MEP Drafting

Before we can solve a problem, we must first understand it. The field of MEP drafting is fraught with common challenges that can derail even the best-laid plans.

- Clash Detection Issues: The most notorious challenge. This occurs when different building systems (e.g., HVAC ducts, sprinkler pipes, and electrical cables) are designed to occupy the same physical space. Without a coordinated approach, these clashes are only discovered on-site, leading to expensive and time-consuming rework.

- Coordination Breakdowns Between Teams: In large projects, architects, structural engineers, and MEP engineers often work in silos. This lack of real-time communication and data sharing can lead to outdated information and design discrepancies that are difficult to resolve.

- Documentation Errors: From missing details and incorrect dimensions to outdated version control, poor documentation is a silent killer. It creates ambiguity, forces contractors to make assumptions, and opens the door to costly mistakes during construction.

- Hidden Costs from Rework and Delays: These challenges are not just technical; they have a direct financial impact. Each hour spent re-routing a pipe or re-fabricating a part is a dollar lost. These costs, often hidden from initial budgets, can quickly sink a project’s profitability.

3. Clash Detection: Identifying and Solving Conflicts

Clash detection is the proactive process of identifying these conflicts before construction begins. It’s a game-changer that moves problem-solving from the chaotic construction site to the controlled digital environment.

- Types of Clashes:

- Hard Clashes: Physical intersections where two components occupy the same space. (e.g., a duct passing through a wall, a pipe hitting a beam).

- Soft Clashes: Space conflicts where a system doesn’t have enough clearance for maintenance or installation. (e.g., not enough room to access a valve).

- The Real-World Impact: An unresolved clash can halt construction, requiring engineers to re-design, fabricators to re-cut, and crews to wait. This domino effect can cause project delays of weeks or even months.

- Software Tools for Early Detection: Modern solutions like Autodesk Navisworks and Revit MEP allow drafters and engineers to virtually “walk through” a combined 3D model, automatically highlighting all clashes. Resolving these issues in the software takes minutes, whereas resolving them on-site can take days.

4. Coordination Issues: Why Teams Struggle & How to Fix It

Miscommunication is the number one reason for coordination failure. Here’s how to fix it:

- Common Reasons for Miscommunication:

- Using different software platforms.

- Sharing files through outdated methods like email.

- Lack of a central communication hub.

- BIM as a Coordination Game-Changer: Building Information Modeling (BIM) is a collaborative process that creates a single, shared digital model. When all teams (architecture, structural, and MEP) work within this model, they can see each other’s work in real-time, instantly spotting potential conflicts. BIM is not just a tool; it’s a workflow.

- Best Practices for Smooth Workflows: Implement a central project management system, schedule regular coordination meetings, and establish clear communication protocols from day one.

5. The Role of Documentation in Project Success

Documentation is the official record of your project. Its quality directly impacts a project’s efficiency and safety.

- Key MEP Documents:

- Design Drawings: The initial set of drawings from the engineer.

- Shop Drawings: Highly detailed drawings prepared by contractors or fabricators for construction and installation.

- As-Built Drawings: A final set of drawings showing the systems as they were actually built on-site, including any changes made during construction.

- How Poor Documentation Creates Risks: Ambiguous or inaccurate drawings can lead to safety risks, improper installations, and legal disputes. A lack of proper as-builts can make future maintenance and renovations nearly impossible.

- Standardization & Version Control: All project teams must agree on a standardized format for drawings and a rigorous version control system to ensure everyone is working from the most current set of documents.

6. Software & Tools That Make Drafting Smarter

The right tools are essential for modern MEP drafting.

- Drafting Tools: AutoCAD MEP and Revit MEP are the industry standards. They are specifically designed for MEP systems, offering pre-built components and intelligent routing tools.

- Clash Detection & Collaboration Tools: Autodesk Navisworks is the gold standard for clash detection. Collaboration platforms like BIM 360 (now Autodesk Construction Cloud) allow teams to work on a single file in the cloud, ensuring real-time updates and seamless coordination.

- Cloud-Based Solutions: Cloud platforms have revolutionized the industry by providing a central hub for all project data, accessible from anywhere. This promotes real-time communication and reduces the risk of working with outdated files.

7. Cost Considerations in MEP Drafting

Poor drafting is expensive, but good drafting is a long-term investment that saves money.

- Direct vs. Indirect Costs:

- Direct Costs: The cost of physically fixing a mistake on-site (e.g., labor, new materials).

- Indirect Costs: The far greater costs of project delays, contractor penalties, and reputational damage.

- How Accurate Drafting Saves Money: By catching clashes in the design phase, you eliminate the need for costly rework. A well-coordinated design ensures smooth construction, keeping the project on schedule and within budget.

- Outsourcing vs. In-House: While in-house teams offer control, outsourcing can provide access to specialized expertise, advanced software, and a flexible workforce, often at a lower cost, especially for smaller or project-based needs.

8. Practical Solutions to Overcome Drafting Challenges

- Implement BIM-Driven Workflows: Adopt BIM as a company-wide standard. This is the single most effective way to improve coordination and reduce clashes.

- Regular Coordination Reviews: Schedule weekly or bi-weekly meetings where all key stakeholders review the integrated BIM model and resolve any identified clashes together.

- Invest in Skilled Drafters: Hire experienced drafters and provide continuous training on the latest software and technologies. A skilled drafter is a valuable asset.

- Leverage AI & Automation: Emerging technologies can automate repetitive tasks, improve clash detection accuracy, and free up drafters to focus on more complex design challenges.

9. Future Trends in MEP Drafting

The field of MEP drafting is rapidly evolving.

- Digital Twin Technology: The creation of a virtual, real-time replica of a building. Digital twins use data from the as-built drawings and sensors to monitor the building’s performance, providing valuable insights for facility management and maintenance.

- AI-Based Clash Detection: AI algorithms can analyze complex models and predict potential clashes with greater accuracy and speed than human drafters, providing a new layer of quality control.

- Sustainable Drafting Practices: As the demand for green buildings grows, MEP drafters are focusing on energy-efficient designs, renewable energy systems, and sustainable material choices.

10. Conclusion: Turning MEP Drafting Challenges into Opportunities

MEP drafting is no longer just a support function; it’s a strategic pillar of modern construction. The challenges of clash detection and coordination are real, but they are also opportunities for innovation.

By adopting BIM workflows, investing in the right technology, and fostering a culture of collaboration, companies can transform their drafting process from a source of problems into a key driver of project success. The future belongs to those who see beyond the lines on a blueprint and recognize that true value lies in precision, coordination, and proactive problem-solving.

Looking for an intelligent approach to your next project? Let the Engineering Geni team bring precision and expertise to your MEP drafting needs.